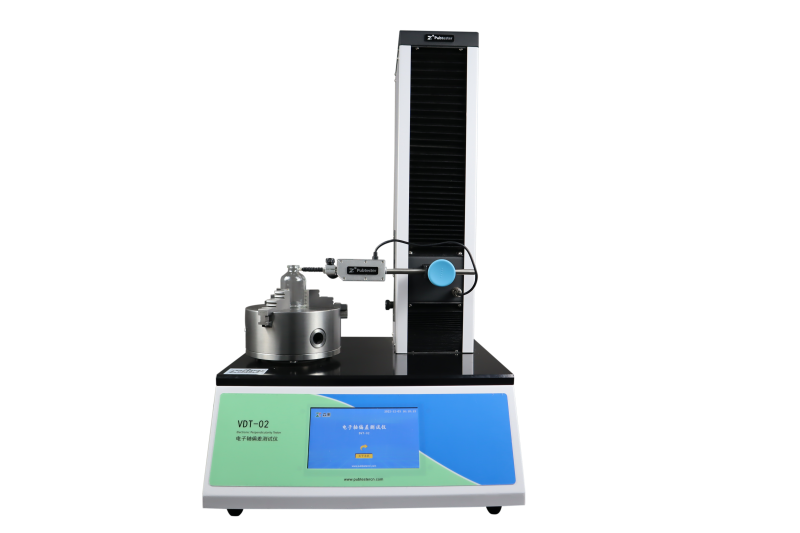

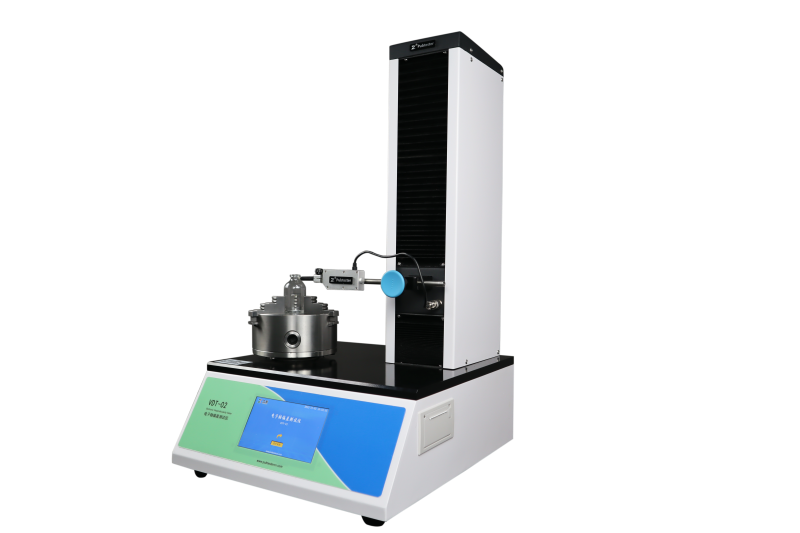

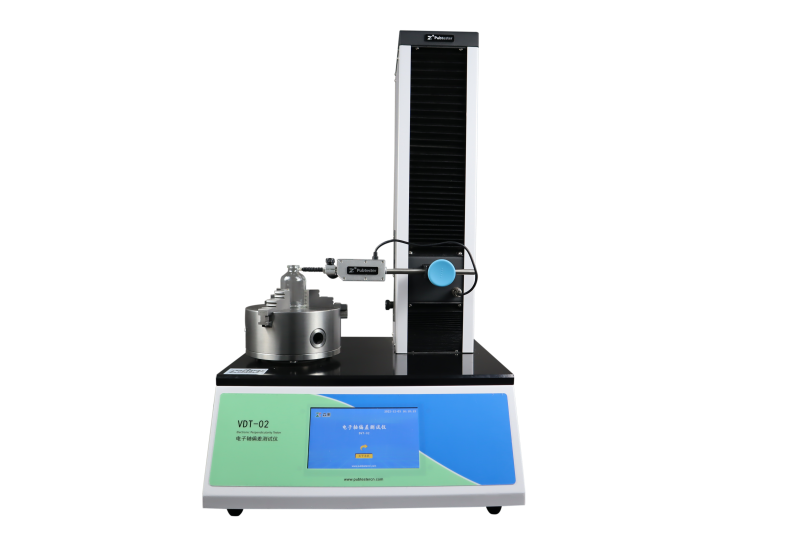

VDT-02 Electronic Axis Deviation Tester

VDT-02 Electronic Axis Deviation Tester is used to determination the vertical deviation of various bottles and containers in food and beverage, cosmetic bottles, pharmaceutical glass containers and other industries.

Product Features

Professional design

Ø 7-inch color touch screen with intelligent data processing functions provides a comfortable and smooth operating experience

Ø Brand motor and ball screw transmission technology to ensure the accuracy of up and down lifting tests

Ø Electronic high-precision displacement sensor, high precision of displacement test

Ø Stainless steel triangular chuck with wide clamping range

Ø Measuring head automatic movements, adjust the position of the measuring point, convenient and practical

Ø Calibrate automatically, which s is simple and convenient

Ø Standard RS232 port for easy transmission of data

Ø Automatic statistical maximum value, minimum value and average value

Ø Equipped with a micro printer that can print test data in real time

Ingenious design

Ø Dual function: circular runout and axis deviation, suitable for ampoules, vials, beverage bottles, beer bottles, etc.

Ø The sensor adopts a quick-plug interface for easy replacement.

Ø With powerful data storage function, which can store up to 100,000 test data.

Ø Data export function (optional)

Safety protection

Ø Limit protection, overload protection, and power-off memory ensure safe operation

Ø Equipped with a limit protection switch to prevent clamp collision caused by displacement overload

Ø The software has an over-range shutdown function to protect the sensor.

Data Security (optional)

Ø Equipped with a four-level user password function to ensure the security of test data

Ø The computer software complies with the requirements of GMP "Computerized System", with functions such as user management, authority management, and data audit trail, etc.

Test Principle

Fix bottle bottom on the horizontal plate to make the bottleneck contact with the dial gauge. Rotate 360°to read the maximum and minimum value,1/2 of maximum and minimum difference is axis vertical deviation value. Self-centering chuck high concentricity characteristics together with a stand which can adjust the height and position freely could meet all kinds container.

Applications

Basic Application | Glass Bottles |

Plastic Bottles |

Medicine Bottles |

Cosmetics Bottles |

Technical Specifications

Specifications | VDT-02 |

Test Item | Vertical axis deviation, circular runout |

Indication error | <0.1mm |

Stroke | 0-12.7 mm |

Displacement Resolution | 0.001mm |

Specimen Diameter | 3-160 mm |

Height Range | 5-400mm |

Holder Speed | 0-30c/min Adjustable |

Probe Lifting Mode | Electric |

Lifting speed | 300mm/min |

Instrument Dimensions | 440mmX460mmX770mm |

Weight | 59Kg |

Power Supply | 220V 50Hz |

Standard:

GB 8452, GB 2639, QB 2357, QB/T 1868, YBB60402012-2015, YBB00332002-2015, YBB00192003-2015

Configuration

Standard Configuration: Instrument, Micro-Printer

Feedback

Feedback 在线咨询

在线咨询

Sales01@pubtestercn.com, Sales02@pubtestercn.com

Sales01@pubtestercn.com, Sales02@pubtestercn.com A3-2, Yinfeng International Biological City, Hi-tech East Zone, Jinan 250104, Shandong, China

A3-2, Yinfeng International Biological City, Hi-tech East Zone, Jinan 250104, Shandong, China