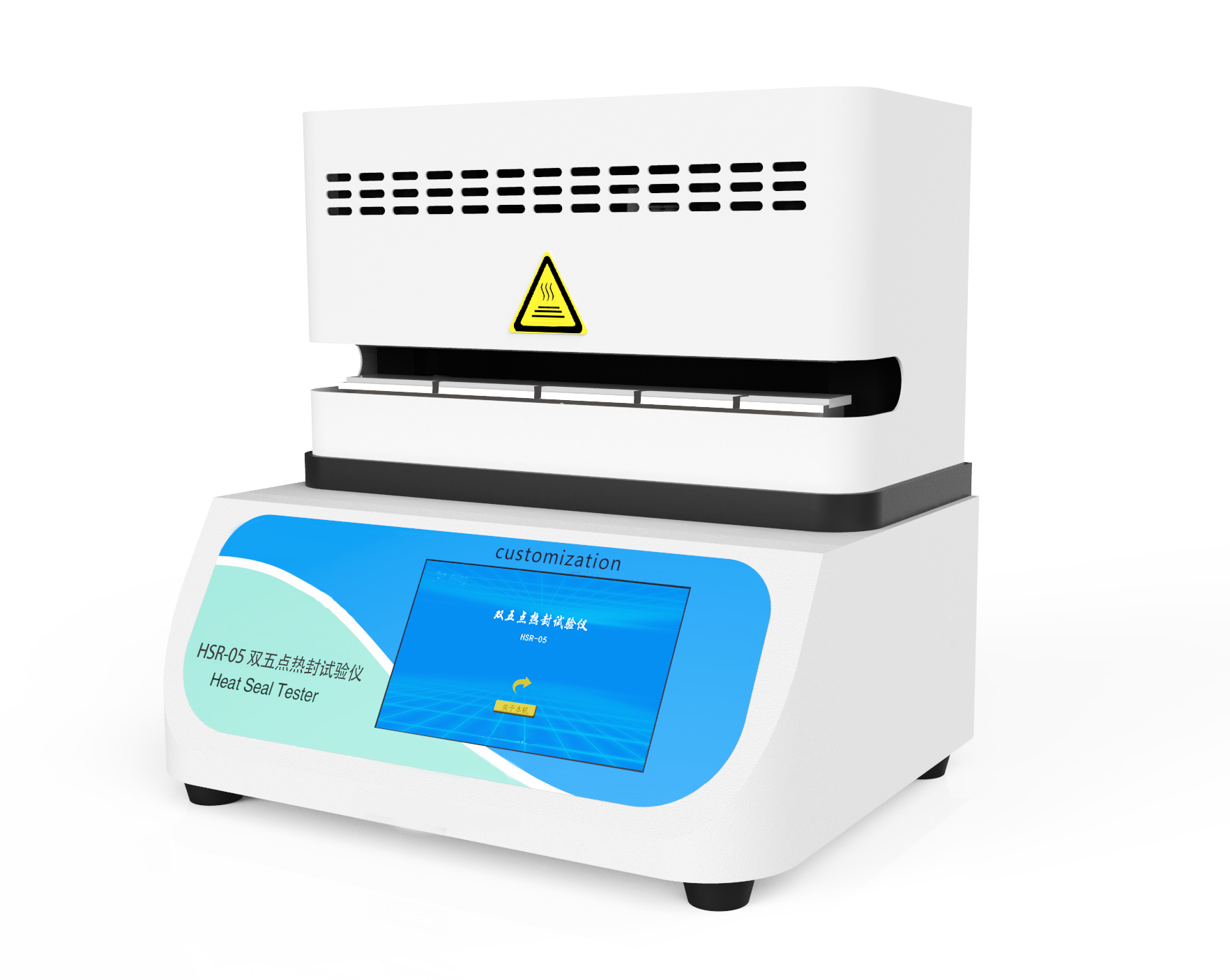

HSR-05 Gradient Heat Seal Tester

HSR-05 Gradient Heat Seal Tester can be used to determine the heat sealing parameters including dwell time, sealing pressure and sealing temperature for plastic films, flexible composite films, plastic coated paper and other heat-sealable films. The melting point, thermal stability, fluidity and thickness are the factors that may influence the heat sealing properties of materials. The heat sealing parameters for those materials are quite different.

Technical Features

Ø Embedded micro-computer chips, simplified and efficient user interface provide users with comfortable and smooth operating experience.

Ø Can complete 5 groups of specimen tests at a time, helps the user to obtain heat sealing parameters of the specimens accurately and efficiently

Ø Five upper sealing jaws controlled by five pneumatic cylinders to ensure the stability of the sealing process

Ø Standard, modularized and systematic designs can meet personalized requirements of the users

Ø 7-inch HD LCD, touch screen interface, displaying test data and curves in real time

Ø Manual or pedal switch, as well as anti-scald design guarantee a convenient and safe operating environment

Ø The temperature of upper sealing jaws and lower sealing jaws can be controlled separately, which can meet the requirements for different combination of temperatures

Ø Digital P.I.D temperature control technology, the preset sealing temperature can be achieved in a short period without fluctuation

Originality Design

Ø Imported high-speed and high-precision chips guarantee the testing accuracy and efficiency

Ø Test parameters such as heat sealing temperature, pressure and dwell time can be input by operating on the touch screen

Ø Patented design of sealing jaws ensures the uniformity of sealing temperature on the sealing surface, the uniformity of the entire heat sealing jaw can reach ±1℃

Ø Test parameters such as heat sealing temperature, pressure and dwell time can be input on the touch screen directly, which is convenient and quick to operate

Ø The width and length of heat sealing jaws can be customized without the influence of structure

Test Principle

HSR-05 Heat Seal Tester makes heat seals by heat sealing method. It can be used to determine the optimal sealing parameters including sealing temperature, sealing pressure and dwell time, for the purpose of determining heat seal ability of flexible barrier materials. Firstly, the sealing temperature, sealing pressure and dwell time should be set on the touch screen and then the instrument will be controlled by embedded micro-processor and run the pneumatic driving mechanism so that the upper sealing jaws will move downward and complete the heat sealing of the packaging materials. By trying different combinations of those sealing parameters, the optimal sealing temperature, sealing pressure and dwell time can be determined.

Applications

Basic Applications | Films | Plastic films, plastic composite films, paper-plastic composite films, coextruded films, aluminum coated films, aluminum foils, aluminum foil composite films and many others. Note: The width of sealing surface can be customized upon user’s requirements. |

Extended Applications | Sealing Surfaces | Various types of sealing surfaces can be customized upon user’s requirements. |

Jelly Cups | Jelly cups can be sealed with special testing accessories. |

Soft Plastic Pipes | Soft plastic tubes can be sealed from one end and become packaging containers |

Technical Specifications

Specifications | HSR-05 |

Sealing Temperature | Room temperature ~ 300 °C |

Sealing Pressure | 0.1MPa ~ 0.7 MPa |

Dwell Time | 0.1~ 999.9s |

Temperature Accuracy | ±0.2 °C |

Temperature Uniformity | ± 1 °C |

Temperature Gradient | ≤20°C |

Heating Mode | Double Heating Surfaces (Independent Control) |

Sealing Area | 40 mm × 10 mm x 5 groups (Customization) |

Power Supply | AC 220V 50Hz / AC 120V 60HZ |

Gas Supply Pressure | 0.1MPa~0.7MPa (Not in Supply Scope) |

Port Size | Φ8 mm PU Tubing |

Instrument Dimension | 400 mm (L) × 320 mm (W) × 500 mm (H) |

Net weight | 70kg |

Standards

ASTM F2029, QB/T 2358, YBB 00122003

Configuration

Standard Configuration:Instrument, Pedal Switch, Micro-printer

Optional Configuration:Communication cable

Note: 1. The gas supply port of the instrument is Φ8 mm PU Tubing;

2. Customers will need to prepare for gas supply.

Feedback

Feedback 在线咨询

在线咨询

Sales01@pubtestercn.com, Sales02@pubtestercn.com

Sales01@pubtestercn.com, Sales02@pubtestercn.com A3-2, Yinfeng International Biological City, Hi-tech East Zone, Jinan 250104, Shandong, China

A3-2, Yinfeng International Biological City, Hi-tech East Zone, Jinan 250104, Shandong, China