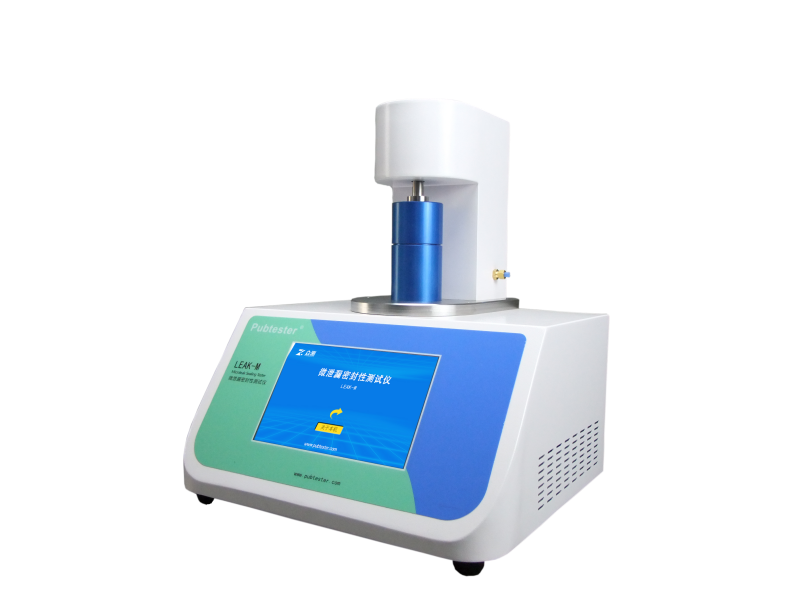

LEAK-M Micro Leak Tester

LEAK-M Micro Leak Tester is designed based on the vacuum decay method and conforms to the requirements of ASTM F2338-09. It is applicable to test the sealing integrity for different volume injection and lyophilized pharmaceuticals such as vials, ampoule bottles, infusion bottles, prefilled syringes, eye drops bottles, liquid filled packaging, non-porous flexible packages, rigid and semi-rigid packaging. It is also suitable for the detection of minimum leakage points and pinholes in blister packaging, semi-rigid or rigid packaging such as glass vials.

Test Principle

The host is connected to a vacuum decay chamber, the sample is put into it and vacuumed, there is a pressure difference between the inside and outside of the sample, and the gas enters the vacuum decay chamber and the host through the leak hole. The host uses a pressure sensor and a differential pressure sensor to monitor the vacuum degree change in the test chamber, judging whether the sample is qualified by the change of vacuum degree.

Applications

Basic Application | Flexible, non-porous packages including bags and pouches containing solids |

Sealed cups or trays containing solids |

Non-lidded, empty cups or trays |

Rigid, non-porous containers including: |

Plastic screw capped bottles containing solids or liquids |

Glass or plastic vials containing liquids or solids |

Glass or plastic ampoules containing liquids |

Glass pre-filled syringes containing liquids or solids |

Ophthalmic dropper tip bottles containing liquids |

Blow Fill Seal bottle or strip containing liquid |

Technical Specifications

Specifications | LEAK-M |

Absolute Vacuum Degree | 10Pa (0.1mbar) |

Sensitivity | 1~3μm pore size |

Authority management | 4 level |

Opening Method | Pneumatic |

Gas Supply Pressure | 0.7 MPa |

Port Size | Φ6 mm PU Tubing |

Display Mode | 10.1”colorful touch screen |

Instrument Dimension | 450mm(L)×390mm(W)×410mm(H) |

Power Supply | AC 220V 50Hz / AC 120V 60HZ |

Net Weight | 26Kg |

Standard:

ASTM F2338, USP1207, YY/T0681.18-2018

Configuration

Standard Configuration: Instrument, 10.1 inch Touch Screen, Vacuum chamber, Vacuum Pump, Micro Printer, Data export system

Optional Configuration: Adjustable flowmeter

Feedback

Feedback 在线咨询

在线咨询

Sales01@pubtestercn.com, Sales02@pubtestercn.com

Sales01@pubtestercn.com, Sales02@pubtestercn.com A3-2, Yinfeng International Biological City, Hi-tech East Zone, Jinan 250104, Shandong, China

A3-2, Yinfeng International Biological City, Hi-tech East Zone, Jinan 250104, Shandong, China