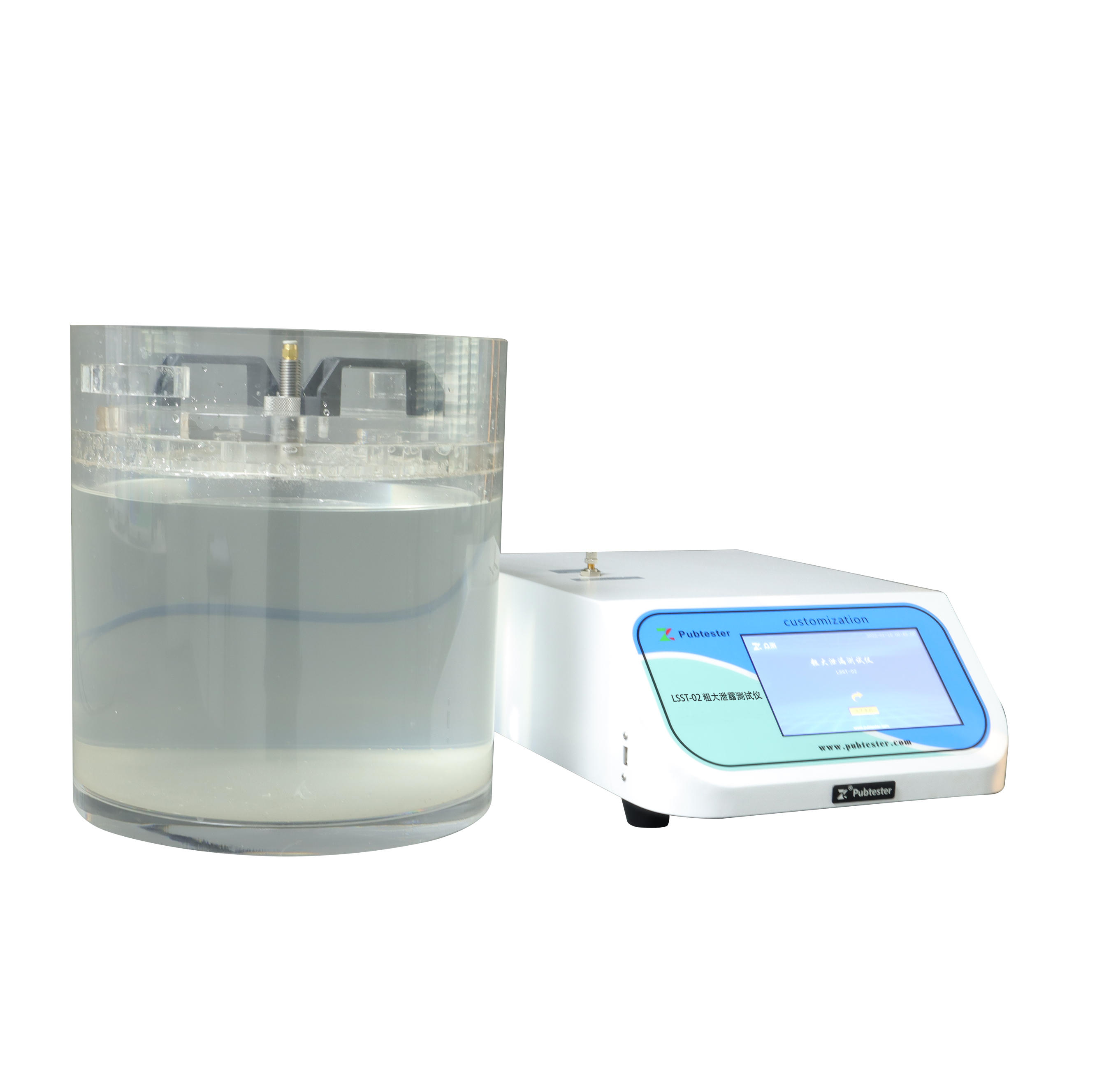

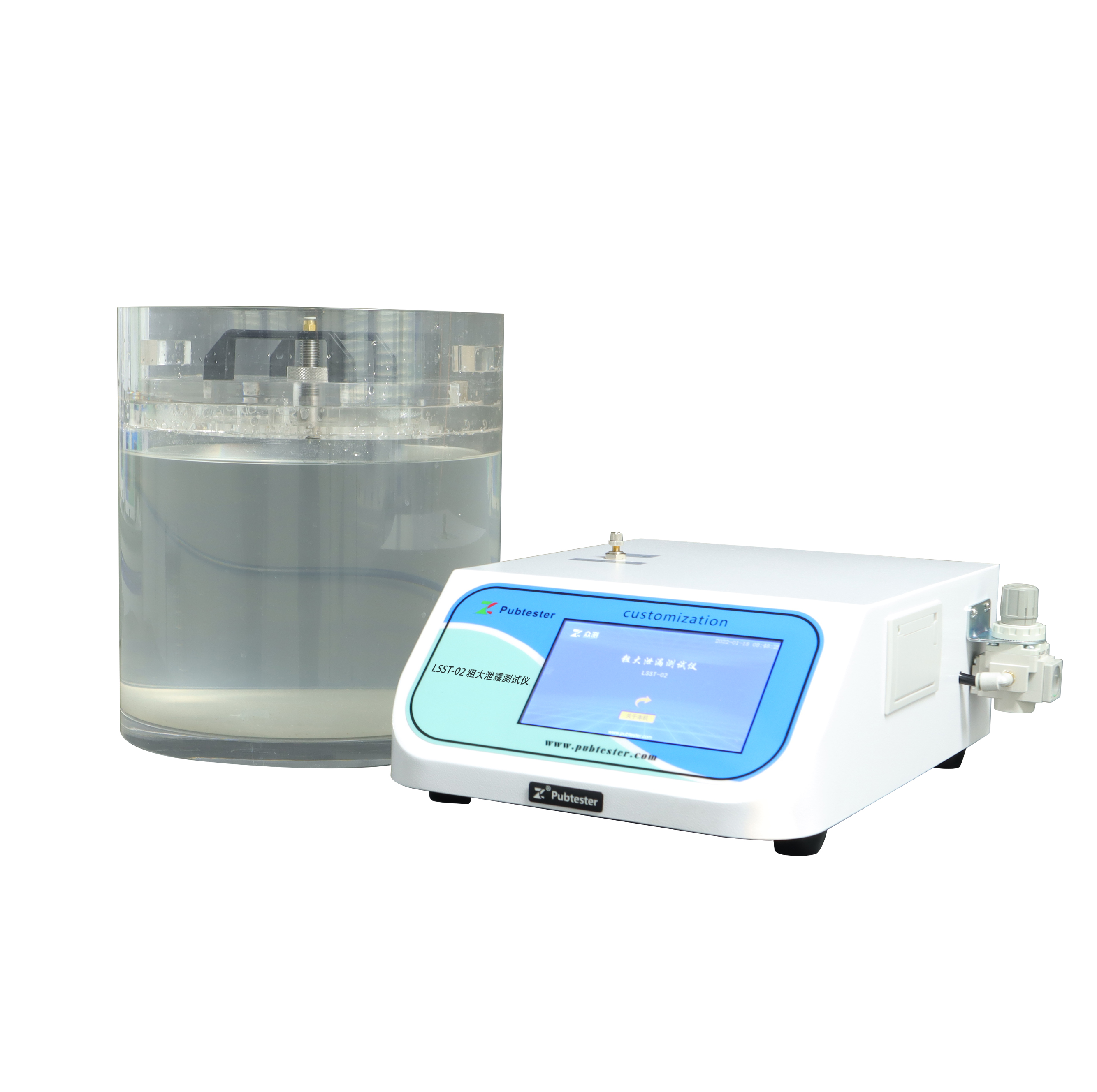

LSST-02 Gross Leak Tester

LSST-02 Gross Leak Tester, adopt positive pressure method, is used to test gross leaks in packaging by internal pressurization (bubble test) of sterile medical device package. It is also applicable to quantitative determination of seal strength, seal quality, burst pressure, seal integrity, compression resistance, torsion force and joint/disengaging force of various flexible packages, aseptic packages, plastic tamper-evident closures, flexible tubes, caps and other materials.

Technical Features

Ø 5 test modes including gross leak, burst, creep, creep-to-failure, pressure maintaining

Ø 7 inch HD LCD, touch screen interface, displaying test data and curves in real time

Ø Dual test methods of restraint distension and unrestraint distension for choice.

Ø Safety design such as over-voltage safety protection and power-down memory ensure the stability of the system

Ø Equipped with standard RS232 interface, which is convenient to PC connection and data transmission

Originality Design

Ø Dual load cells for large and small test range, expand the test range

Ø Adopts high-precision electronic flow controller to realize precise control of gas flow

Ø Pressure and time can be preset

Ø With a powerful data storage function, storing up to 100,000 test records

Ø Results are automatically determined and test data can be printed

Ø The test frame and inflatable head can be raised and lowered for easy operation

Ø Provide various customized leak test functions

Test Principle

There are 5 test modes:

Burst Test: Test the maximum burst pressure of the package (the maximum pressure that the package bears until it fails).

Creep Test: Test the seal strength of the package (the pressure drop value of the package within specific time).

Creep to Failure Test: Test the seal strength of the package (Time to failure of the test package after the set pressure drop value).

Pressure Maintaining Test: Test the seal strength of the package (The test package maintains a specified pressure for a specific time).

Gross Leak Test: Test gross leaks in packaging by internal pressurization (bubble test).

Applications

Basic Application | Gross Leak test | Gross Leak test of various packaging bags and boxes |

Extended Application | Burst Test | Burst strength tests of various packaging bags, boxes and bottles |

Creep Test | Creep tests of various packaging bags and boxes |

Creep-to-failure Test | Creep-to-failure tests of various packaging bags and boxes |

Pressure Maintenance Test |

|

High-pressure Test | The maximum pressure applied can be 1.6MPa |

Pilfer-proof Closure | Seal performance tests of various pilfer-proof closures |

Three-sided Sealing Materials | Tests of packaging bags with three-sided seal and one-sided open |

Compression Resistance of Medical Blister Pack | Tests of various blister packs |

Soft Tubes | Tests of various soft tubes for daily chemical products including toothpaste, facial cleaner, cosmetics as well as medical creams and some food products |

Aerosol Valves | Tests of various aerosol valves, e.g. vales of pesticide, hair spray, auto spray paint and medical spray packages |

Technical Specifications

Specifications | LSST-02 |

Test Range | Sensor 1: 0~600kPa; 0~87psi (Standard) Sensor 2: 0~10kpa; 0~1.45psi (Standard) 0~1.6 MPa;0~232.1 psi (optional) |

Gas Injection Head Dimension | Φ10mm (Standard), Φ4mm, Φ1.6mm (Optional) |

Gas Supply Pressure | 0.4MPa~0.7MPa (Not in supply scope) |

Port Size | Φ8mm PU tubing |

Number of sensors | 2 |

Instrument Dimension | 370mm(L)×310mm(W)×150mm(H) |

Pedestal Size | 356mm(L)×305mm(W)×325mm(H) |

Power Supply | AC 220V 50Hz/110V 60Hz |

Net Weight | 25kg |

Standards

ASTM F2096, ASTM F2054, ASTM F1140, ISO 11607-1, ISO 11607-2, GB 18454, GB 19741, GB 10440, GB 17447, GB/T 17876, GB/T 10004, GB/T 10005, BB/T 0003, BB/T 0025, QB/T 1871, YBB 00162002, YBB 00252005

Configuration

Standard configuration: Instrument, 7” Touch screen, Dual Sensors, Micro-printer, Gross leak test fixture (Test chamber)

Optional Configuration: Professional software, Communication cable, Test Accessories (Test Frame, Fixtures for Closed Package Restraining Test, Open Package Unrestrained Test, Fixture for Plastic Pilfer-proof Closure Test, Flexible Tube Test and Aerosol Vale Seal Performance and Test Device for Blister Pack Seal Performance).

Note: 1. The gas supply port of the instrument is Φ8 mm PU Tubing;

2. Customers will need to prepare for gas supply.

Feedback

Feedback 在线咨询

在线咨询

Sales01@pubtestercn.com, Sales02@pubtestercn.com

Sales01@pubtestercn.com, Sales02@pubtestercn.com A3-2, Yinfeng International Biological City, Hi-tech East Zone, Jinan 250104, Shandong, China

A3-2, Yinfeng International Biological City, Hi-tech East Zone, Jinan 250104, Shandong, China